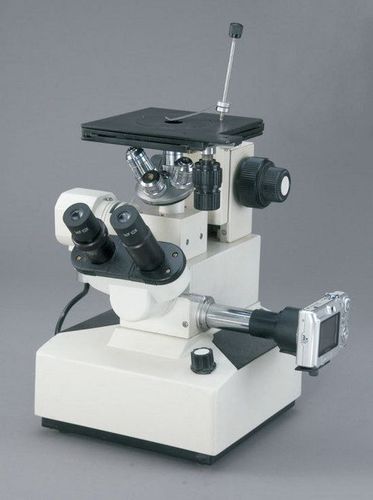

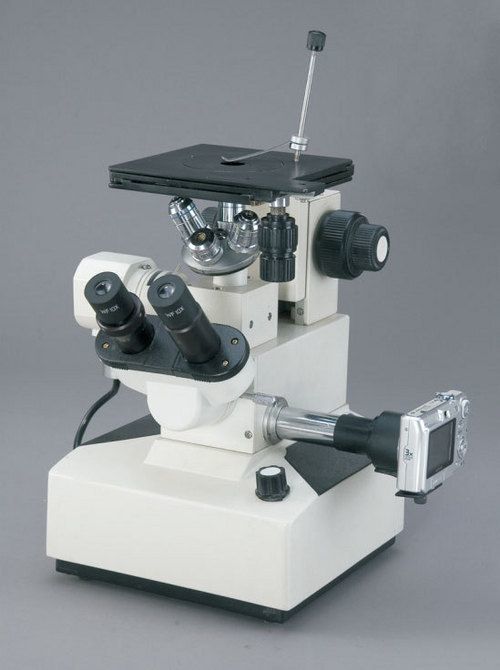

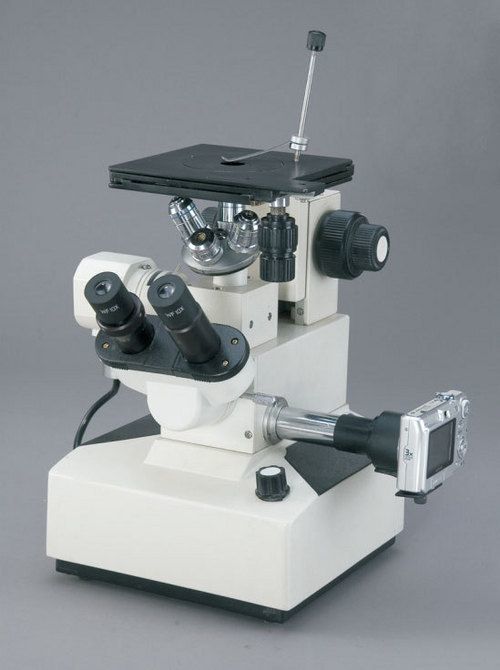

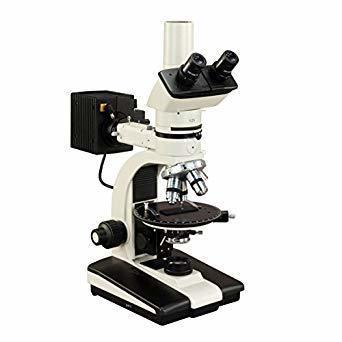

Research Inverted Metallurgical Microscope

32000 INR/Piece

Product Details:

- View Head Trinocular, splitting ratio 20:80

- Focus System Coaxial coarse and fine focusing mechanism

- Spare Parts Fuses, adjustable transformer, halogen lamp, dust cover, immersion oil

- Features Shock-resistant body, ergonomic design, anti-fungal optics, suitable for large or irregular samples.

- Theory Inverted metallurgical microscopes are designed for observation of metallographic structures in metals and alloys. They provide an inverted view to accommodate larger specimens.

- Drawtube Trinocular

- Sensor CMOS digital camera compatible (optional)

- Click to View more

X

Research Inverted Metallurgical Microscope Price And Quantity

- 32000.00 - 40000.00 INR/Piece

- 32000 INR/Piece

- 1 Piece

Research Inverted Metallurgical Microscope Product Specifications

- 55-75mm adjustable

- Coarse stroke approx. 20mm; Fine stroke 2m/division

- Trinocular

- Shock-resistant body, ergonomic design, anti-fungal optics, suitable for large or irregular samples.

- CMOS digital camera compatible (optional)

- 1920 x 1080 pixels at 30fps (using digital camera)

- Approx. 20mm

- 50x to 1000x (using combined objectives and eyepieces)

- Approx. 530 x 225 x 575mm

- Inclined 45, rotatable 360

- Achromatic objectives 10x, 20x, 40x, 100x (Oil)

- Long working distance condenser (N.A. 0.4)

- 2m per division

- Up to 1920 x 1080 pixels (when digital camera is attached)

- Focal length depends on objective lens; Typically 45mm

- Wide field 10x (paired) with adjustable diopter

- 6V 30W halogen lamp with variable intensity control

- Trinocular, splitting ratio 20:80

- Coaxial coarse and fine focusing mechanism

- USB for digital camera (optional attachment)

- 30 fps (when digital camera is attached)

- JPEG, BMP, TIFF (when using digital camera)

- 1920 x 1080 pixels (using digital camera)

- Halogen Lamp 6V 30W

- Fuses, adjustable transformer, halogen lamp, dust cover, immersion oil

- Inverted metallurgical microscopes are designed for observation of metallographic structures in metals and alloys. They provide an inverted view to accommodate larger specimens.

- Mechanical stage with X-Y movement, Stage size approx. 242 x 200mm, Movement range 30 x 30mm

Research Inverted Metallurgical Microscope Trade Information

- AMBALA

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID)

- 5 Piece Per Week

- 7 Days

- Yes

- Free samples are available

- South America, Western Europe, Australia, North America, Eastern Europe, Central America, Africa, Middle East, Asia

- All India

- CE, ISO 9001:2015

Product Description

Side & top with eyepiece tube Binocular observation head inclined at 30º

- interpupillary distances adjustment range from 55 to 75mm.

- Main body : All parts die cast to provide long life & good mechanical strength. Coaxial

- focusing control knobs, tension adjustment ring & pre focusing lock.

- Eyepiece : 10x (16mm).

- Objectives : PL10x, PL25x, PL40x, PL60x (optional).

- Nosepiece : Quadruple nosepiece revolves on ball bearing.

Robust Construction for Precision Analysis

Built from cast aluminum alloy, this inverted metallurgical microscope features a single-column arm with anti-vibration characteristics, supporting stable and accurate sample observation. The sealed viewing tube and lens covers protect delicate optics from dust, maintaining clear imagery even during extended use. Advanced multi-layer optical coatings guarantee reduced glare and enhanced contrast for in-depth evaluations.

Advanced Optical and Imaging Capabilities

With infinity-corrected achromatic objectives and wide-field 10x eyepieces, users can access a broad magnification range, from 50x to 1000x. The trinocular head permits direct attachment of a CMOS digital camera for detailed image and video capture. Brightfield observation, simple polarization, and ergonomic features make it versatile for diverse metallurgical and materials science applications.

Convenient Sample Navigation and Heat Management

Precise mechanical stage movement via coaxial X-Y controls and micrometer adjustments enables accurate navigation of samples, including large or irregular specimens. Built-in cooling vents efficiently dissipate heat generated by the powerful 6V 30W halogen lamp, ensuring continuous operation and consistent performance across research, inspection, and industrial settings.

FAQs of Research Inverted Metallurgical Microscope:

Q: How does the coaxial X-Y stage movement improve sample navigation?

A: The microscopes mechanical stage features coaxial X-Y controls with micrometer adjustments, allowing users to navigate specimens smoothly and precisely. This design enhances accuracy, especially when examining fine metallographic structures or relocating points of interest on samples up to 50mm thick.Q: What are the benefits of an inverted design in metallurgical microscopes?

A: An inverted structure enables observation of larger or irregularly shaped specimens without the need to section them. This setup is ideal for metallographic analysis, as it accommodates samples like polished metal blocks, which are common in materials research and industrial quality control.Q: When is simple polarization observation used with this microscope?

A: Simple polarization is employed when researchers need to analyze structures that exhibit birefringence, such as certain metallic phases or inclusions. The microscope supports basic polarization, providing more detailed visualization beyond standard brightfield observation.Q: Where can this microscope be utilized effectively?

A: This inverted metallurgical microscope is suitable for laboratories, research institutions, industrial quality control labs, and educational facilities. It is especially beneficial in metallurgical research, alloy development, and failure analysis settings across manufacturing firms and academic departments.Q: What is the process for capturing digital images and video with this microscope?

A: By attaching a compatible CMOS digital camera to the trinocular head, users can record high-resolution images (JPEG, BMP, TIFF) and videos (up to 1920 x 1080 pixels at 30fps). The USB interface enables quick download and editing of captured data for documentation and analysis.Q: How does the built-in cooling vent system help during microscope usage?

A: Integrated cooling vents dissipate heat produced by the halogen lamp illumination, preventing the microscope and optics from overheating. This supports continuous operation and preserves image quality and instrument longevity, making it reliable for extended research sessions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Microscope' category

|

AJANTA EXPORT INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese