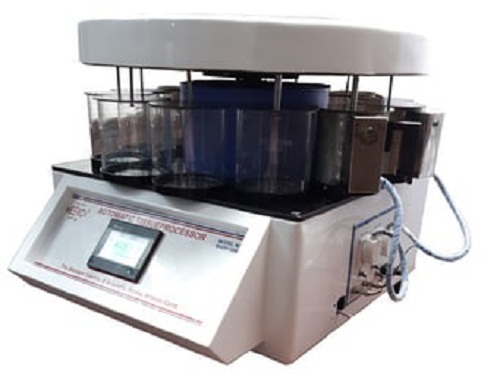

Microprocessor Tissue Processor

98500 INR/Piece

Product Details:

- Display Type Digital LCD

- Accuracy High precision cycle timing

- Features Programmable cycles, LCD display, Digital timer, Safety interlocks

- Frequency 50/60 Hz

- Instruments Type Histopathology Equipment

- Measurement Range Multiple specimen sizes

- Usage Type Laboratory

- Click to View more

X

Microprocessor Tissue Processor Price And Quantity

- 98500 INR/Piece

- 1 Piece

- 98500.00 - 100000.00 INR/Piece

Microprocessor Tissue Processor Product Specifications

- Electric

- Histopathology Equipment

- 700 x 400 x 400 mm

- Automated tissue fixation, dehydration, clearing, and impregnation

- Laboratory

- Microprocessor Tissue Processor

- Store in dry place, avoid direct sunlight

- White and Blue

- Approximately 25 kg

- Multiple specimen sizes

- 250 W

- No

- Digital LCD

- Automatic

- Histopathology and Tissue Processing

- 220-240 V AC

- Low

- 50/60 Hz

- Programmable cycles, LCD display, Digital timer, Safety interlocks

- Yes

- High precision cycle timing

- Stainless Steel and High-Grade Plastic

- No

- New

- Microprocessor Controlled

Microprocessor Tissue Processor Trade Information

- Delhi

- Letter of Credit (L/C), Paypal, Telegraphic Transfer (T/T)

- 15 Piece Per Week

- 7 Days

- Yes

- If order is confirmed we will reimburse the sample cost

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- All India

- ISO, CE, FDA, WHO-GMP

Product Description

Microprocessor Tissue Processor

Feather touch keypad with digital display for adjusting timingsequence Wax bath temperature range from ambient to 80 deg C withindicator to communicate heating status

Advanced Microprocessor Control

The tissue processor is equipped with microprocessor technology, enabling high precision in cycle timing and real-time operation. Users benefit from automated programming and customization, ensuring optimal tissue processing outcomes. Up to nine user-defined programs can be stored in its non-volatile internal memory for frequent usage.

Superior Safety Mechanisms

Engineered with user safety in mind, the unit includes overheat protection, audible alarms, secure lid locking, and safety interlocks. Cycle end notifications ensure laboratory staff is promptly informed, reducing the risk of errors and maximizing operational reliability.

Easy Cleaning and Maintenance

Its detachable parts facilitate thorough cleaning, allowing users to maintain laboratory hygiene standards without hassle. The sealed reagent containers minimize evaporation, and the universal tissue basket accommodates multiple cassette sizes, streamlining the entire workflow.

FAQ's of Microprocessor Tissue Processor:

Q: How does the Microprocessor Tissue Processor improve laboratory workflow in histopathology?

A: This equipment automates routine tissue processing steps such as fixation, dehydration, clearing, and impregnation, reducing manual handling. With programmable cycles and real-time control, it streamlines specimen preparation, increases throughput, and enhances laboratory efficiency.Q: What safety features are included in the tissue processor for user protection?

A: The processor includes overheat protection, audible alarms, lid lock mechanisms, and programmable safety interlocks. These features prevent accidents, notify operators of cycle completion, and protect both specimens and laboratory staff during operation.Q: When should the tissue processor be cleaned, and what procedures should be followed?

A: Regular cleaning is recommended after each processing cycle or at least daily to maintain performance and hygiene. Detachable parts can be easily removed for cleaning, and users should follow manufacturer guidelines using appropriate non-corrosive agents to ensure longevity.Q: Where is the processor typically installed, and can it be wall-mounted?

A: This tissue processor is designed for stationary use on laboratory benches. It is not suitable for wall mounting due to its size and weight (approximately 25 kg). Carefully position it in a dry area away from direct sunlight, within a temperature range of 10C to 40C.Q: What is the benefit of having up to 9 user-defined programs available?

A: Storing multiple customized processing cycles in internal non-volatile memory allows laboratories to handle diverse specimen types efficiently. It saves setup time, increases consistency, and supports rapid workflow adaptation to varying protocols.Q: How are reagents handled to minimize evaporation during tissue processing?

A: Sealed reagent containers are used within the processor. This design minimizes evaporation, maintains reagent integrity, and ensures reliable specimen processing outcomes while reducing operational costs due to reagent loss.Q: Can the processor handle multiple specimen sizes in one cycle, and how?

A: Yes, the universal tissue basket accommodates various cassette sizes, enabling simultaneous processing of multiple specimens. This supports efficient batch workflows and flexibility for different laboratory requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Histopathology Equipment' category

|

AJANTA EXPORT INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese