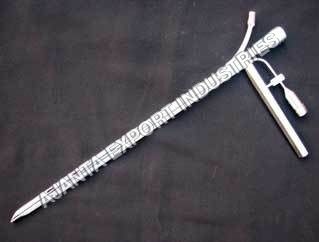

LENS EDGERS

Product Details:

- Equipment Type LENS EDGERS

- Material ABS Plastic

- Technology Laser

- Driven Method Manual

- Weight 4-8 Kilograms (kg)

- Usage For Hospital

- Click to View more

LENS EDGERS Price And Quantity

- 1 , , Piece

- 60000 INR/Piece

LENS EDGERS Product Specifications

- Laser

- 4-8 Kilograms (kg)

- ABS Plastic

- LENS EDGERS

- For Hospital

- Manual

LENS EDGERS Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 1 , , Piece Per Week

- 1 Week

- Western Europe, Australia, North America, Eastern Europe, Middle East, South America, Asia, Central America, Africa

- All India

Product Description

We are a prominent manufacturer and supplier of a wide gamut of Auto Lens Edger that is designed using the most-advanced technology under the supervision of skilled professionals. The offered Auto Edger is available in different technical specifications, which fit the diverse requirements of the clients.

| SPECIFICATION | Magnificent lenses |

|---|

Precision Edge Finishing

Benefit from the accuracy of laser technology integrated into the manual LENS EDGERS. These machines deliver consistent and precise lens edging, crucial for creating custom eyewear suited for hospital and distribution needs. Their construction from ABS plastic ensures both durability and safety during operation.

User-Friendly Manual Operation

Designed with a focus on user adaptability, the manual-driven LENS EDGERS give technicians hands-on control while shaping lenses. This feature allows operators in hospitals and supply chains to address a variety of lens requirements efficiently and reliably, without the need for automated systems.

FAQ's of LENS EDGERS:

Q: How are LENS EDGERS operated in a hospital or supply setting?

A: LENS EDGERS are manually operated, allowing technicians to control the edging process directly. This ensures the custom shaping of lenses to precise requirements, making them ideal for hospital and supply environments.Q: What materials are used in the construction of these manual lens edgers?

A: These LENS EDGERS are made from ABS plastic, a material known for its durability and lightweight properties, which enhances portability and ease of maintenance.Q: When should manual LENS EDGERS be used instead of automated options?

A: Manual LENS EDGERS are best suited for scenarios that demand detailed, hands-on customization, such as small-scale production in hospitals, clinics, or laboratories requiring precise and controlled edging.Q: Where can these LENS EDGERS be sourced in India?

A: These LENS EDGERS are available through various channels in India including authorized distributors, exporters, manufacturers, suppliers, and trusted medical equipment traders.Q: What is the process for edging a lens using this equipment?

A: The process involves placing the lens into the edger, then manually guiding the lens along the machine while the laser technology ensures accurate shaping and finishing according to the required specifications.Q: How does laser technology benefit the use of manual LENS EDGERS?

A: Laser technology in these edgers provides enhanced precision, resulting in smoother and more accurate lens edges. This technological feature is particularly beneficial for complex prescriptions and specialized eyewear.Q: What are the main benefits of having a manually-driven LENS EDGER weighing 4-8 kg?

A: The compact and lightweight design makes the edger portable and easy to integrate into various workspaces. Manual operation ensures greater control, while the robust ABS plastic material and laser technology combine efficiency with long-term durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Ophthalmic Equipment' category

|

AJANTA EXPORT INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese