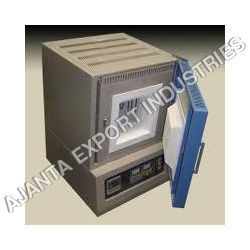

Leak Test Apparatus

Product Details:

- Features Vacuum Release Valve, Digital Timer, Acrylic Vacuum Chamber, Easy to Operate

- Temperature Resistance Upto 100C

- Speed Range 0 - 600 mmHg (Adjustable Vacuum)

- Glass Type Borosilicate

- Display Type Digital Display

- Power Supply AC Mains

- Shape Rectangular

- Click to View more

Leak Test Apparatus Price And Quantity

- 1 Piece

- 6000 INR/Piece

Leak Test Apparatus Product Specifications

- Leak Test Apparatus

- 25 W

- Vacuum Release Valve, Digital Timer, Acrylic Vacuum Chamber, Easy to Operate

- For Laboratory use

- Stainless Steel with Acrylic Chamber

- 220 Volt (v)

- Leak Test Apparatus

- Digital Display

- 350 x 300 x 220 mm

- 6 Liters

- Leak Testing of Blister Packs, Strips, Bottles, Tablets, and Capsules

- 0 - 600 mmHg (Adjustable Vacuum)

- Table Top Leak Test Apparatus

- Upto 100C

- AC Mains

- Rectangular

- Stainless Steel

- Digital Timer & Touch Keypad

- Borosilicate

- 2 mmHg

Leak Test Apparatus Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 7 Piece Per Week

- 1 Week

- Western Europe, Australia, Eastern Europe, Middle East, Central America, Africa, South America, Asia, North America

- All India

Product Description

Description:

Being a well known manufacturer of packaging machine, our organization offers Leak Test Apparatus. The apparatus is an ideal instrument to check sealing integrity of blister packs, strip packs, sachet and pouch packs etc. Further, it is also helpful for checking leaks from capped bottles, induction sealed containers, sealed or crimped tubes etc.

The apparatus is very compact which saves lot of valuable place in process laboratories.

Our new Leak Test Apparatus has been manufactured as per GMP guidelines having stainless steel body with phenomenal compactness has replaced the old method of separate desiccator. Equipped with long lasting vacuum pump, which gives higher level of vacuum in shortest possible time. It has die pressed polycarbonate vacuum desiccator that helps the vacuum to sustain for a longer period. Moreover, for disconnecting the vacuum source, a vacuum gauge is provided indicating vacuum level which is connected to isolation valve. There is a timer ranging 0 to 5 minutes that helps the operator in avoiding the need of continuous running of vacuum pump.

Specification:

| Dessicator Diameter | 150 mm | 300 mm |

| Rating | 5A 230V Single Phase | 5A 230V |

| Single Phase Vacuum Level | 22" Hg | 22" Hg |

| Timer | 5 minute (mechanical) | 5 minute (mechanical) |

| Dessicator Polycarbonate | Polycarbonate | Polycarbonate |

| Body | Stainless Steel | Stainless Steel |

| Actual Size | 14"(W)x9"x(D)x10"(H) | 22"(W)x17"(D)x19"(H) |

Advanced Leak Testing for Laboratory Needs

Designed for laboratories, this apparatus streamlines leak testing of pharmaceutical packaging. Its oil-free, maintenance-friendly vacuum pump and clear acrylic chamber allow safe, real-time observation. With digital timer controls and soft touch keypads, operators can precisely set test parameters. Automatic vacuum release and gasket-fitted lids enhance safety, making it reliable for daily lab procedures.

Key Features and Performance

A durable stainless steel housing pairs with an acrylic vacuum chamber, ensuring both robustness and clear observation during tests. The digital control panel features an easy-to-read display, while vacuum accuracy is maintained within 2 mmHg. The chamber accommodates up to 6 liters, operates at up to 100C, and delivers consistent performance across a 0-600 mmHg vacuum range, adhering to IP/USP compliance for pharmaceutical testing.

FAQ's of Leak Test Apparatus:

Q: How is the Leak Test Apparatus used in laboratory settings?

A: This leak test apparatus is primarily used for assessing the seal integrity of pharmaceutical packages such as blister packs, bottles, tablets, and capsules by applying a controlled vacuum inside a transparent acrylic chamber and monitoring for leaks.Q: What are the benefits of a transparent polycarbonate or acrylic chamber?

A: The transparent material allows operators to visually inspect the sample during testing, helping identify leaks or defects instantly while ensuring chemical resistance and durability.Q: When should I use the digital timer and how does it work?

A: The digital timer, with a range up to 999 seconds, allows you to set the duration of each test. The vacuum is maintained for the set period, after which the automatic vacuum release feature ensures safe completion of the test.Q: What is the process for adjusting vacuum levels during a test?

A: Vacuum levels, adjustable from 0-600 mmHg with 2 mmHg accuracy, are regulated through the membrane soft touch keypad. The real-time vacuum level is displayed on the digital panel for precise control during testing.Q: Where can this leak test apparatus be used?

A: It is designed for laboratory use, especially in quality control departments of pharmaceutical manufacturing and research facilities, due to its compact size and compliant performance.Q: How does the automatic vacuum release enhance user safety?

A: At the end of the test period, the system automatically releases the vacuum, reducing risk for users and maintaining the integrity of the tested samples by preventing overexposure to vacuum conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Scientific Instruments' category

|

AJANTA EXPORT INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese