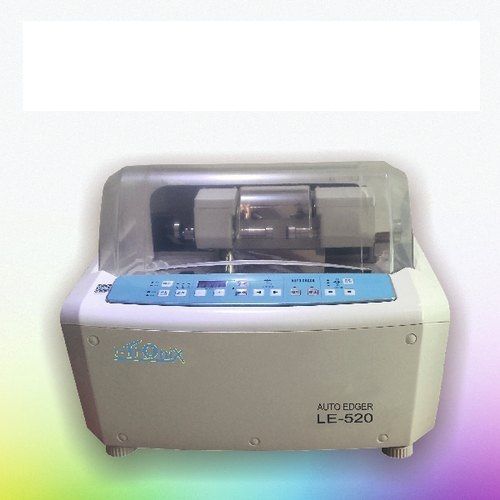

Autolens Edger

130000 INR/Piece

Product Details:

- Equipment Type Automatic Lens Edger

- Material Stainless Steel, ABS Body

- Technology Auto Edging Technology

- Properties High Precision, Durable, User-Friendly Interface

- Grade Ophthalmic Lab Grade

- Lens Specification Glass and Plastic Compatible

- Lens Diameter 22 mm - 110 mm

- Click to View more

X

Autolens Edger Price And Quantity

- 130000 INR/Piece

- 130000.00 - 150000.00 INR/Piece

- 1 Piece

Autolens Edger Product Specifications

- 540 mm x 340 mm x 290 mm

- Electric Motor

- 220V / 50Hz

- 0 - 6

- 22 mm - 110 mm

- Ophthalmic Lab Grade

- 28 kg

- Glass and Plastic Compatible

- Automatic Lens Edger

- High Precision, Durable, User-Friendly Interface

- Stainless Steel, ABS Body

- 120W

- Edging and Shaping Prescription Lenses

- Auto Edging Technology

- No

Autolens Edger Trade Information

- AMBALA

- Cash Against Delivery (CAD), Cash on Delivery (COD), Paypal, Cash in Advance (CID), Cheque, Cash Advance (CA)

- 1000 Piece Per Month

- 7 Days

- If order is confirmed we will reimburse the sample cost

- Western Europe, Australia, Eastern Europe, Central America, Middle East, South America, Asia, North America, Africa

- All India

- CE,ISO

Product Description

Product Specification| Brand | AJANTA |

| Power Supply | 20+-10 50Hz |

| Unit Weight | 50 Kg |

| Power Consumption | 500W |

| Technical parameter | Min22mm Max100mm |

| Range of adjustable measurement | -6.0mm - +6.0 mm 0.05 mm/step |

| Dimension of figure | 510mm X 490 mm X 40 mm |

| Minimum Order Quantity | 1 Piece |

- Flat polishing wheel

- Bevel polishing.

- Rough grindindg wheel for glass lenses.

- Bevel fine grinding wheel.

- Flat fine grinding wheel.

- Rough grinding wheel for CR and PC lenses.

- Speed of resin lens grinding is higher.

Advanced Auto Edging Technology

Engineered for ophthalmic lab environments, the Autolens Edger incorporates cutting-edge auto edging technology for highly precise shaping of prescription lenses. Its multi-lens setting memory and digital LCD touch screen streamline complex jobs, offering user-friendly navigation and customization for lens requirements.

Enhanced Safety and Efficiency

The machine is equipped with automatic stop and overload protection to enhance operator safety. Its electric motor and low noise operation ensure efficient, quiet performance. Integrated automatic water circulation aids in lens cooling and efficient cutting, supporting a smooth workflow in busy optical settings.

Versatile and Durable Construction

Built with stainless steel and ABS body, the Autolens Edger is robust and suitable for rigorous, daily use. It accommodates a wide range of lens diameters and materials, supporting both glass and plastic. The diamond wheel guarantees consistent performance and durability over extended use.

FAQ's of Autolens Edger:

Q: How does the Autolens Edger contribute to efficient lens processing in optical shops or laboratories?

A: With its approximate 90-second edging speed per lens and automatic operation, the Autolens Edger significantly boosts productivity and consistency for optical professionals, making it ideal for high-demand environments.Q: What types of lenses is the Autolens Edger compatible with?

A: This edger supports both glass and plastic lenses, accommodating diameters from 22 mm to 110 mm, and is adjustable for prisms up to 6. Its versatility makes it suitable for a broad array of prescription lens tasks.Q: When is the automatic stop and overload protection feature activated?

A: The automatic stop and overload protection functions are triggered if the machine detects abnormal pressure or resistance, ensuring user safety and preventing damage to the device or lens during operation.Q: Where is the Autolens Edger most commonly installed and who are its typical users?

A: It is most often installed in optical shops and ophthalmic laboratories. Typical users include opticians, lab technicians, and eye care professionals who require accurate and efficient lens edging solutions.Q: What is the process for using the digital LCD touch screen interface?

A: Users navigate the intuitive touch screen to select lens settings, modes (groove or bevel), and store multi-lens preferences. This interface simplifies operational steps, reducing manual input and potential errors.Q: How does the automatic water circulation benefit lens edging?

A: The automatic water circulation system effectively cools the lens and cutting wheel during operation, reducing friction, preventing overheating, and ensuring smooth, precise edging results.Q: What are the primary benefits of using the Autolens Edger for prescription lens shaping?

A: Its key advantages include rapid edging time, reliable precision, compatibility with diverse lens sizes and materials, low noise performance, robust safety features, and long-term durability thanks to its quality build materials.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Ent & Ophthalmic Equipment' category

|

AJANTA EXPORT INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese